1 | Furnace stripped Castable being replaced with Ceramic Fibre

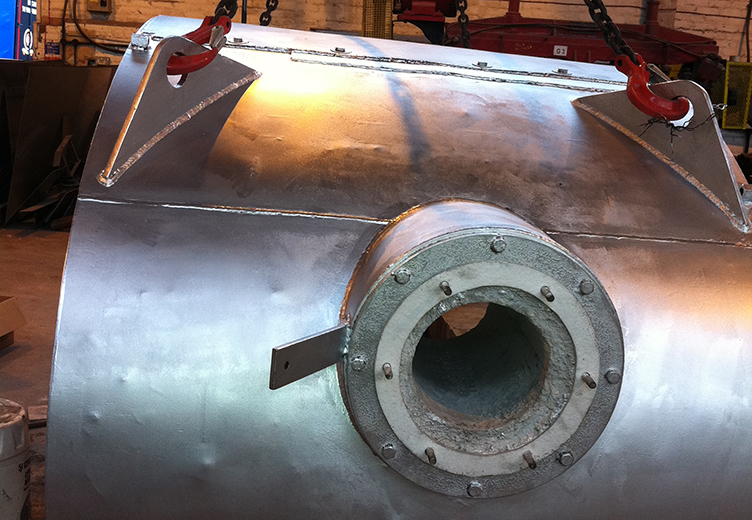

2 | End on view with cast insitu

Burner Port

3 | Furnace completed for

return to client

4 | Furnace positioned ready

for production

Historically Etchells OEM Series Eleptical Forging Furnaces have traditionally been lined with High Alumina Furnace Bricks and a high density castable lining, which whilst having the ability to withstand the arduous conditions of the drop forging furnace environment are inherently not energy efficient. The heat up time from ambient to forging temperature can be a significant factor in production considerations; this is principally due to the time taken to overcome the thermal inertia of the refractory lining and bringing billet stock up to forging temperature.

New gas fired burners were sourced and mounted to the furnace complete with new gas control train, combustion air and door curtain fans, finished out with a new state of the art control panel.

Following long and detailed discussions with our client, which necessitated overcoming their reticence of the transition from a tried and tested traditional method of lining this type of furnace, our client achieved the confidence in our ability and expertise, such that they decided to instruct us and have one complete furnace lined, where

possible with and being mindful of the potential for physical material charging damage, the maximum amount of 170Kg/M³ density Ceramic Fibre lining that we were able to install which was located in all areas not subject to contact with charged stock.

This furnace then subsequently achieved a dramatically increased heat up time to forging temperature which increased the production availability throughput of the furnace, additionally, incorporating the added advantage and benefit of an energy efficient reduction in gas usage.

This furnace has been in operation now for approaching two years and when stripped, the Ceramic Fibre lining was found to be in reasonably good order with no signs of major mechanical damage due to contact with the charged stock

Telephone +44 (0) 1384 564160

FAX +44 (0) 1384 635628 72 Bannister Street, Cradley Heath, Warley, B64 5EQ

© Industrial Combustion Engineers Ltd. 2023.

Website design by Steve Jolliffe